WHAT IS SINGLE PAIR ETHERNET?

Technology

SMART AND STRONG

Single Pair Ethernet (SPE) describes the transmission of Ethernet over only one pair of copper wires. In addition to data transmission via Ethernet, SPE also enables a simultaneous power supply of terminal devices via PoDL - Power over Data Line. Previously, this required two pairs for Fast Ethernet (100MB) and four pairs for Gigabit Ethernet. SPE now opens up completely new possibilities and fields of application for Industrial Ethernet.

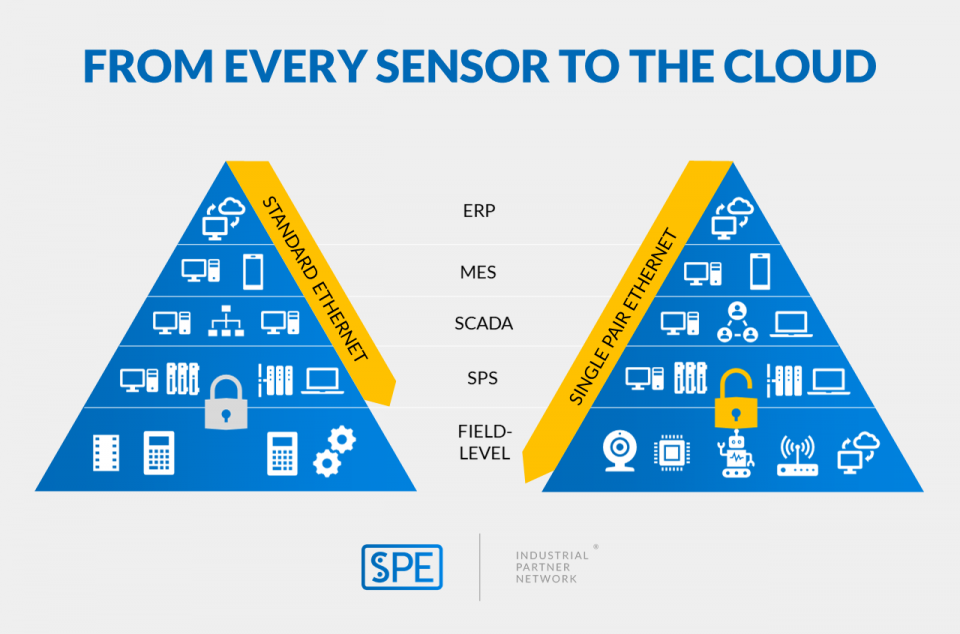

In industrial networks, Ethernet has in the past initially prevailed from the company level via the operation and process level right up to the control level. The last level of the automation pyramid, the field level, is classically connected via various BUS systems. One reason for this is the fine branching and the large number of devices in the field level. Hundreds to thousands of sensors and actuators in a production plant have to be connected via extensive peripherals consisting of cables. All in all, a considerable amount of cables and a cost factor. In addition, gateways and translators are always needed to translate the data of both worlds into each other.

Recently, the need for more efficient infrastructure at the field level has grown significantly. More and more sensors require transmission rates that BUS systems can no longer provide. At the same time, the existing Ethernet infrastructure is too expensive, too large and oversized for most field applications. This applies to cables, connectors and device components. A slim, lightweight yet powerful infrastructure for Ethernet was needed to enable the industry to digitize at the field level and thus take the step into IIoT. This is where SPE comes in.

The industry wants to take advantage of the benefits of this slim cabling. In automation, SPE allows the barrier-free connection of field devices, sensor/actuator technology and much more. The field level becomes smart and thus reduces the effort for parameterisation, initialisation and programming. The construction, operation and maintenance of systems becomes more efficient and cost-effective. For the first time, Ethernet can communicate space- and cost-efficiently from the cloud to the field level.

SPE in machines, robots or railway technology also contributes to weight and space savings. The entire cabling becomes simpler and can also be installed much faster.

ONE INSTEAD OF FOUR PAIRS -

A TECHNOLOGICAL GAMECHANGER

THE INFRASTRUCTURE FOR IIOT

Ethernet with TCP/IP makes every field participant intelligent. With TSN (Time Sensitive Network) they also become real-time capable and can therefore also be used for safety-relevant cabling. In contrast to BUS systems, the significantly increased data transmission rate will also allow sensors with high data volumes to be connected cost-effectively in the future. For example, camera vision systems for recognition and positioning systems. Previously, such sensors had to be separately guided into the field with an 8-wire Ethernet infrastructure. With SPE, each sensor can be uniformly connected to the Internet. T1 Industrial device interfaces and SPE cables according to ISO/IEC 11801-X form the standardized infrastructure for SPE at the field level. Slim as conventional BUS infrastructure, but significantly more powerful in data rate and simultaneous power transmission. Every small sensor becomes a smart participant in the industrial Internet of Things.

IS SPE REPLACING EXISTING ETHERNET INFRASTRUCTURE?

Most likely not. In the current state of development and standardization, SPE transmits 1 GBit/s only up to a distance of 40 meters. 8-wire Ethernet, however, up to 100 meters transmission length. In addition, a large number of interfaces and devices would have to be converted, which is not necessary. Ethernet via just one pair of wires is used where advantages arise through enormous space and weight savings. These are, for example, applications in the railway industry. Here, less weight means enormous cost saving potential.

Ethernet is gaining more and more relevance in automation and is becoming more and more accepted as a universal medium. BUS systems, on the other hand, are constantly in retreat. It is precisely in this area, from the control level to the field level, that SPE BUS systems will lose market share. The miniaturized SPE standard interface for industrial applications, T1 Industrial style according to IEC 63171-6, can efficiently reach every sensor and actuator in the field in conjunction with slim SPE cables.

SAFETY THROUGH STANDARDS

IEC 63171-6

ISO/IEC 11801-X

TIA 42.X

IEEE 802.3

IEC 63171-6 THE INDUSTRY STANDARD FOR SPE INTERFACES

IEC 63171-6 was published in early 2020, making it the world's first standard for SPE connections in industrial applications adopted by all major standards bodies. Already submitted in 2016, the complete standard document includes all necessary specifications and test sequences for simple and reliable implementation.

ISO/IEC JTC 1/SC 25/WG3 & TIA42 WIRING STANDARDS - FOR FULL COMPATIBILITY

For a secure end-to-end connection, all components of the infrastructure must meet uniform standards. So do the cables.

These cabling standards provide the user with information about the structure of the cabling, the cabling components to be used to achieve the performance targets and the limits for checking the cabling. This makes them the most important instrument for setting up and commissioning SPE cabling. At the same time, they ensure compatibility between devices and cabling through references to component standards (e.g. connectors according to IEC 63171-6). This compatibility is a basic prerequisite for the function of networks and connections based on SPE and thus the basis for IoT/IIoT. The use of cabling components other than, for example, ISO/IEC 11801-3 Amd.1 is possible in principle, but then no longer conforms to standards and carries the risk of incompatibilities and functional losses.

ISO/IEC JTC 1/SC 25/WG 3 and TIA42 therefore started international selection processes at the beginning of 2018 to define uniform interfaces. These two selection processes were initiated in part by IEEE 802.3, which requested a recommendation for a SPE MDI (SPE device interface) from ISO/IEC and TIA.

More than 20 national expert committees participated in this selection process. As a result of this election, two plug-in faces have prevailed:

for building cabling (M1I1C1E1) the mating face according to IEC 63171-1:

this mating face is based on the proposal of the company CommScope;

for industrial and industry-related applications (M2I2C2E2 and M3I3C3E3) the mating face according to IEC 63171-6 (previously IEC 61076-3-125):

this mating face is based on the proposal of HARTING T1 Industrial.

IEEE 802.3

The Ethernet protocol standards according to IEEE802.3 define the technical framework conditions for Ethernet transmission via only one wire pair. An important committee with trend-setting competence. Without a uniform protocol, there is no open standard. To support this interaction of standardized components for a holistic ECO system, IEEE802.3 follows the recommendations of ISO/IEC JTC 1/SC 25/WG 3 and TIA42 for a uniform SPE interface and also recommends T1 Industrial style (IEC63171-6) as the standard SPE interface for industrial applications.